The production line mainly licludes :

Feeding platform , driven motor , reduction gears , driven motor , reduction gears , driven system , roll forming rollers , and computer control cabinet ,ect . This line adopts alternting current motor to drive, and formed by welded by welded steel sheet welded , which makes more reliable and stronger

The main technical parameters of corrugated forming machine are as follows:

| 1 | Dipped galvanized sheet, galvalume sheet, color steel sheet. (Hardness HRB<90°>80°) |

| 2 | Width:≤1000mm |

| 3 | Thickness:0.12~0.35mm (Multiple cumulative thickness can reach 0.7mm) |

| 4 | Length:≤3100mm |

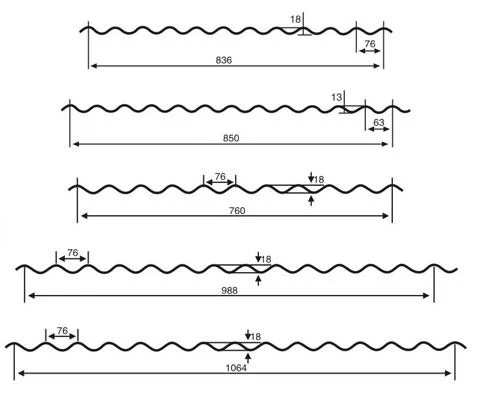

Corrugated sheet size: (length × wave height × wave length):≤3100mm×18mm×76mm

<Wave height and wave length are adjustable, wave height increases, wave length decreases; conversely wave height decreases, wave length increases>

A,Structure description

It consists of a forming roll, a correction roll, and a frame. Four rollers share a motor ,Reducer drive.

Forming roller: the number is two pieces, when the assembly is arranged up and down, through the transmission shaft and reducer connected to the transmission molding roller operation to complete the tile in the rolling process of power.

Correction roller: The number is two. When assembling, it is arranged up and down. It is connected with the gear box through the transmission shaft and the correction roller is operated to correct the wave height and tile width of the roll forming plate.

B,Forming roller, correction roller adjustment

Forming roller, correction roller are up and down adjustable.

The forming roller lift adjustment handlebar adjusts the wave width of the unit width tile, adjusts the width of the tile width at the beginning and end of the tile, and the peak-to-peak width of the tile.

The correction roller lift adjustment handle is used to adjust the width of the forming tile and the height of the tile peak. The adjustment device has scale and dial indicators that allow precise adjustment of the required parameters.

C,Feeding platform device

Feeding platform is a frame structure, which is composed of a lower fixed frame and an upper movable frame. The movable platform is a reciprocating motion of the connecting rod crank. The reciprocating support is a linear motion bearing with high precision support, and the plate is flushed into the forming roller. Positioning the adjustable stop, the position of the stop can be precisely adjusted by the scale indication

D,Transmission Device

The power input of the entire device is the transmission of the motor gearbox through the drive shaft, the speed of the equipment is adjustable through the inverter, and the speed adjustment range is wide.

E,Electric control system

One frequency conversion control box is used to complete the control of the equipment production process.